1 July 2016 posted by Kelly Brown

We often get asked about what the difference is between a “hazard” and a “risk”? Often it is felt that the two terms mean the same thing. With the new WHS laws, it is important for your business to differentiate between these terms and what they actually mean. We’ve made a downloadable safety glossary so you can easily identify and differentiate a range of safety terms that often appear in legislation.

What does hazard mean?

A “hazard” means a situation or thing that has the potential to harm a person. Hazards in your business may include: noisy machinery, a moving forklift, chemicals, electricity, working at heights or a repetitive job at your workplace.

What does risk mean?

A “risk” is the possibility that harm (death, injury or illness) might occur when exposed to a hazard in your workplace.

Another important safety risk management term to your business:

“Risk control” means your business taking action to eliminate health and safety risks so far as is reasonably practicable, and if that is not possible, minimising the risks so far as is reasonably practicable. Eliminating a hazard will also eliminate any risks associated with that hazard in your workplace.

Safety terms and definitions are often surrounded by technical jargon, making them difficult to understand. You can download our handy glossary of safety terms to use when you’re faced with those tricky expressions.

A proactive approach should be taken in your workplace to identify hazards and a common way of doing this is to have a workplace inspection checklist with possible hazards that are relevant to your industry and workplace.

Examples of what are a hazard and risk

- HAZARD: Frequent bending to load a pallet with boxes. RISK: A manual handling injury to the back

- HAZARD: A hot-tempered supervisor screaming at staff. RISK: A mental health issue for a staff member.

- HAZARD: An extension cord running across a frequently used hallway. RISK: A trip and possible injury resulting.

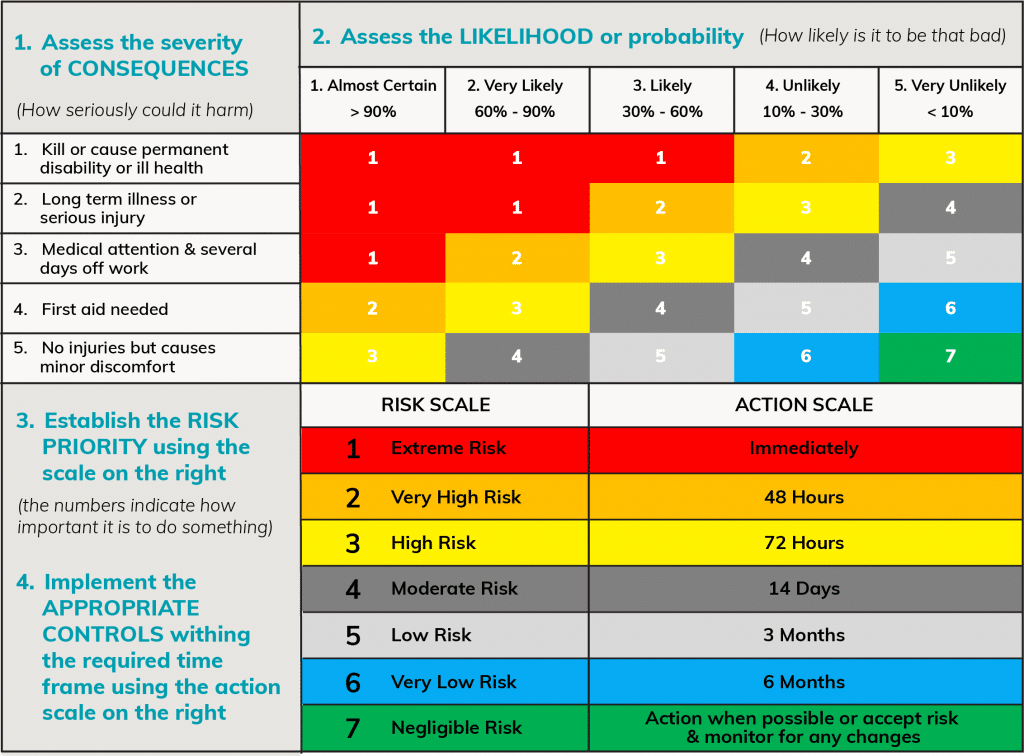

The risk management approach also encourages priority given to higher risk hazards over lower risk. The easiest way to do this is with the use of a risk matrix that has two considerations. Likelihood and consequence. How likely is an injury to occur and if it did what could be a possible consequence in terms of severity of the injury. Below is a simple but very useful risk matrix.

If we take the first hazard dot point above and use the matrix we could say a long-term injury (point 2 of consequence axis) could result from poor manual handling practices. We could also estimate that given the worker does the task 15 times a day for 15 minutes that the likelihood is ‘likely’. (Point 3 of likelihood axis). Where the two axis intersect, gives us the RISK. In this case, it’s a 2 so it’s a very high risk per the matrix.

It’s irrelevant what matrix you use as it’s subjective and everyone will have a different opinion on exactly what the likelihood and consequence is. The point of the matrix is if you have 100 hazards in your business now you may only have 6 that are rated high risk or above. These are the risks you should focus on FIRST.

Source Document: Code Of Practice: How To Manage Work Health And Safety Risks 2018

Disclaimer – these articles are provided to supply general safety information to people responsible for OHS in their organisation. They are general in nature and do not substitute for legal and/or professional advice. We always suggest that organisations obtain information specific to their needs. Additional information can be found at https://www.safeworkaustralia.gov.au/

Recent Posts

What is a Return to Work Coordinator?

10 May 20244 Reasons Why You Can’t Be Complacent with Workplace Health and Safety

1 May 2024What is the difference between Functional Capacity Evaluation and Fitness for Duties?

23 April 20244 Safety Checklists You Need Right Now

10 April 2024Why protecting your employee’s mental health matters